We are happy to share some of our Jumpstart Fellows experiences and accomplishments. The reflections from these Jumpstart students reinforce the need for these types of programs and we’re grateful to the participating companies for their hospitality, opening their doors to our students, working with and mentoring them, treating them as valued employees, and giving them meaningful work and experience that inspire their futures. The goal of the Jumpstart program is to encourage and empower diverse high school girls to pursue careers in robotics and promote the diversity of the robotics workforce by giving them a solid foundation of technical skills as well as a professional network to give them the confidence and support they need to pursue a career in the tech field.

The Cohort 4 program curriculum ran from January to May 2024, every Saturday and through the February school vacation. Students’ coursework included design, fabrication, engineering and coding as well as programming around soft skills, networking and working in a professional environment.

In August (2024) our students had a final session where they shared their internship experience with each other through presentations to the group – including their employers. These students had the unique opportunity to work with companies that truly believe in the potential of young minds, providing them with real professional experiences before college even begins.

A huge thank you to all the companies who support our mission by hiring Jumpstart Fellows to intern at their companies this summer — their mentorship and guidance are invaluable.

GreenSight is a founding partner and collaborator of our Jumpstart program and has hosted multiple interns annually, including hiring returning interns from previous cohorts!! Greensight took four interns this summer.

Fellows reflections:

Catherine (rising senior at North Quincy High School)

At GreenSight, I explored robotics, mechanical, and electrical engineering while working under a range of projects—most notably, WeatherHive. WxH aims to provide an autonomous solution for gathering weather data, and it deploys WISPS (drones) from a Hive (station) to conduct missions. I gained a diverse set of skills and experiences while contributing to the current phase of the project.

In the domain of mechanical engineering, I assembled Hives and prepared parts in the machine shop. In the domain of electrical engineering, I made wire harnesses and assisted in board testing. Further, I researched and experimented with thermopile sensors to progress an early design feature in the drones to applicability. Along the way, I spent my days in the laboratory, CADed numerous components, soldered countless wires, and learned from a team of both kind and knowledgeable engineers.

Not only did I grow as a professional and developed a valuable technical background, I also discovered more about myself in this internship. I am more than ever hooked on this discipline dedicated to problem solving, this world of designing, testing, and building machines & structures.

A special thanks to the incredible mentors at Greensight, from my amazing supervisor to engineers passing by my desk that were always willing to help. And, of course, thanks to MassRobotics for providing this priceless opportunity.

Mirudulaa (rising senior at Quincy High School)

At Greensight, I had the privilege of delving into a broad spectrum of advanced topics from college level physics to deep understanding of electrical and mechanical engineering, Greensight has taught how to succeed as a tenacious worker in the robotics field. My supervisor, Oliver, has spent countless hours making sure that I not only learned the topics, but was also able to properly apply it to the field in real life scenarios. Other people, such as Joel, Maria, Mike, Eli, and Janice, have made sure that I get a vast exposure to new concepts, tasks, and skills to make my experience unforgettable.

I worked under various projects, most notably the SeaJelly, a bioinspired, biomimetic soft aquatic robot that harnesses the flow of water, rather than air, to make use of actuators to move underwater. I was able to contribute hugely to the project by designing, testing, and using CAD software to come up with a better and more advanced design. In fact, this design was presented to MassRobotics during the BlueTech Academy last month, where I was able to help others build, understand, and learn from SeaJelly.

Additionally, I helped with the hive assembly for the WeatherHive and CAD modeling and electrical research (awg wires, crimps, micro fit connector, flange connector, digikey, and molex), tons of 3D printing (for SeaJelly and SPAMR project), and Python for numerous other projects. Throughout the internship, I had the opportunity to advance my skills of soldering, electrical component and PCB boards, format for PDR sessions, CAD, and most importantly the understanding of who I am as a female in STEM. I’m really grateful for this amazing opportunity, thanks to Joyce, Kevin, Joel, and the whole team of Greensight.ole team of Greensight.

Alana (rising senior at Milton High School)

This summer at Greensight, I was assigned to SeaJelly but I wanted more of a challenge in addition to engineering hands on projects and advocated for something different. I tried out coding and loved it. I rapidly advanced my coding skills in numerous languages such as Python, Java, SQL, C++ and Lua. Coding on projects like ATAK and WeatherHive was perfect for me because it allowed me to really think outside the box in a fun way as if it was a puzzle.

My favorite project so far has been using Data Science to analyze geo mapping on Greensight’s Turf Cloud Software. When first introduced to this project by Kyle I had minimal experience in computer science but he was able to quickly give me the tools I needed to succeed. I was able to write a Python script that would return the tlogs of a drones flight which included essential information such as the heights of the drone, the position of the drone in relation to latitude and longitude, and how long the flight was. With this information I was able to create graphs and tables to estimate the length of future flights depending on a courses size or location on Earth’s coordinates.

I would like to firstly thank my MassRobotics Jumpstart Mentors for introducing me to the field of computer science and the Greensight Company. I would also like to thank Greensight’s numerous engineers and computer scientists that made my Greensight internship a welcoming and knowledgeable experience!

Michelle (rising senior at Boston Latin School)

During my time at GreenSight, I was able to work across different projects and meet numerous people who all helped to further my learning and skills in the realm of engineering.

From research on palm trees to programing PDBs to testing weather sensors, the information I learned regarding PCBs, CADing, soldering, mechanical assembly, design, etc. will be invaluable for my future. Alongside the other JumpStart interns, I was work on WeatherHive, helping to assemble Hives in the shop along with wiring and assembling cables.

I was also able to spend a substantial amount time CADing and 3D-printing. Beyond just learning how to convert a STL file to a STEP file and how to perform maintenance on a 3D printers, the experience gave me more insight into what I was interested in and also how much I was capable of.

GreenSight has provided me with a welcoming environment filled with encouraging people who were always ready to help and answer my questions. Thanks to the employees of GreenSight who made this summer a rewarding one (especially my supervisor Mike) and thank you to MassRobotics for helping to make this internship possible.

Ruth (rising senior at MIT, Jumpstart Cohort 1 Alumni)

As a mechanical engineering intern at GreenSight, I had the opportunity to work on a variety of projects. One of the first I helped with was an axial flux motor. I used a computer aided design software, to 3D model an improved assembly of the stator and rotor. I also designed and 3D printed an innovative jig to facilitate the adhesion of magnets to the rotor. Additionally, I worked on SeaJelly, a bio-inspired aquatic robot used for STEM education. In particular, I conducted waterproof testing on various prototypes of a 3D printed canister and lid assembly, which contain sensitive electronics. I also taught high schoolers to build their very own SeaJellys.

Another short project I had was constructing a mount for a fixed-wing drone to launch off of. I learned to make the most of limited time and materials to assemble a stable and functioning launch pad. Lastly, near the end of my internship I had the opportunity to go to Oklahoma to collect data with weather-detection drones. I got experience working in the field (literally!), doing live debugging and observing autonomous flights.

Emily (Northeastern University incoming freshman) and Alison (rising junior at Somerville High School) had their internship at WSP/Odeh Engineers

Odeh Engineers is a structural engineering firm that specializes in the design and evaluation of many buildings throughout the U.S.. They joined WSP in 2022 adding expertise to their engineering and professional services company, which include complex markets like healthcare and science and technology, as well as commercial, residential, higher education, cultural, government, manufacturing and other key sectors.

At their internships, the Fellows had the opportunity to rotate through several of WSP’s engineering departments including Odeh Structural Engineers, Transportation Infrastructure Group, Land Surveying and Mechanical, Electrical, Plumbing (MEP). They made site visits to HarbourVest, Harvard Enterprise Research Campus (ERC), State Street and the Winthrop Center and used technologies including Bluebeam, Revit, Enercalc, Mathcad and Autodesk Revit

Emily shares , “ I’m grateful for this experience because it showed me how broad engineering is, beyond the traditional types of engineering. I was able to observe the daily lives of different engineers and why they chose this career path. It really helped me identify what I enjoy and what I might want to avoid in my future career.” She goes on to say, “ I learned the importance of collaboration and how all types of engineering are needed to work together to deliver a successful project. Experiencing the culture at WSP really deepened my understanding of what it is like to work in the engineering industry!”

Tori Jiang (incoming Freshman at Purdue University)

MITRE is an engineering facility which supports multiple government projects in healthcare, homeland security and cybersecurity. The company has created many devices to innovate in the advanced maritime space. The assembly of these machines must be recorded to allow for their replication and improvement. However, it is nearly impossible to accurately describe the assembly of such complicated apparatuses using basic instruction manuals.

This is where my role comes in. Currently, I am working on interactive personal documentation to clearly illustrate the assembly of these devices. In SolidWorks Composer player, users can click on different components to see details about the part as well as see how it is used in the machine. Interactive instructions make assembly easier, more efficient, and a bit more fun as well. Through this project, I have learned how to use Solid Works Composer as well as strengthen my Linux and Git Hub skills. I have learned so much throughout this internship, and I am sure that the skills I have learned at my time in MITRE will help me thrive professionally in the future.

Rebeca (Incoming Freshman at Boston College) and Kate (rising senior at Cambridge Rindge and Latin School)

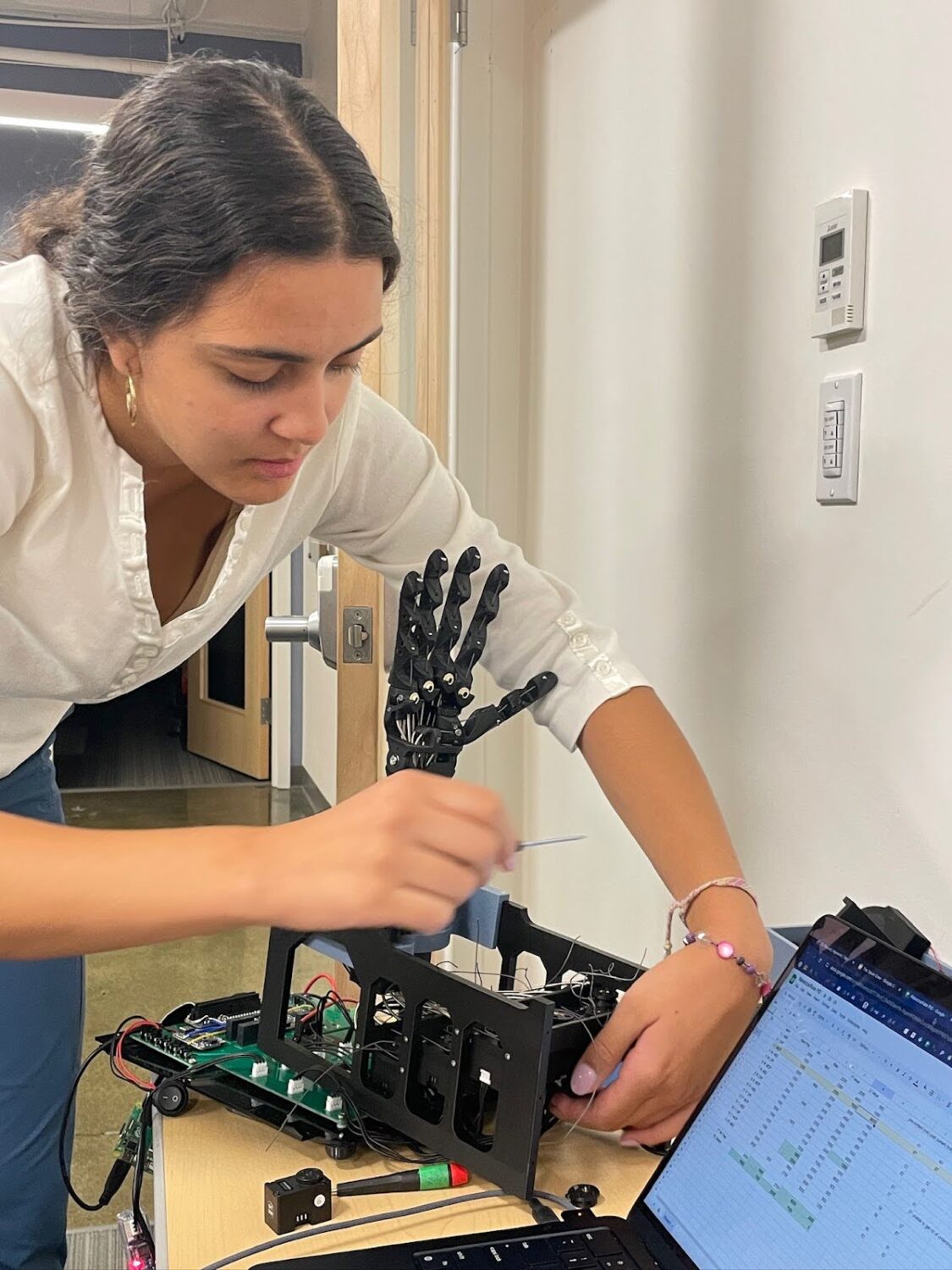

Tatum Robotics is a company dedicated to advancing assistive technologies for the DeafBlind. The DeafBlind communicate through Tactile Sign Language, a variation of Sign Language that involves keeping the signing hand or hands in contact with the other person, so they can track both signs and movements. This becomes an issue when the use of touch between people is limited, as it was with social distancing in 2020, when Tatum’s founder Samantha Johnson first began her masters thesis, a project that would go on to become Tatum Robotics. She read about the struggles of the DeafBlind to operate independently with scarce methods of communication, and began to create a robotic fingerspelling hand that could be used for virtual tactile signing. Today, the company continues to develop the Tatum T1 hand, bringing it step by step closer to widespread use. Additionally, they are looking to the future, considering other applications and versions of their product. For instance, in education, where individualized attention is necessary for the DeafBlind, but inefficient and costly, there is a need for tools like Tatum’s Hand that can foster independent learning. The close-knit company has also mastered lunchtime, making sure to eat together every day (even when table space is limited), and whose employees are a collection of unlikely chefs, as demonstrated at the occasional flawless potluck.

Throughout our internship we had the privilege of going deeper into the skills we learned in the Jumpstart program. Our project at Tatum focused on redesigning the robot for use of smaller lower voltage motors. Our project poses the benefit of more efficient use of material and a new avenue for a smaller hand used for children in elementary education. We began our task in 3d design through CAD software, designing models that both maximize space and function and are capable of supporting the necessary hardware. We learned to consider the types of materials, fasteners, and mechanics and their importance in design intent. Tangentially, we quickly became acquainted with 3d printing and hardware assembly, understanding the constraints and design implications of 3d printing. In our efforts to test the effectiveness of the smaller motors, we completed PID tuning and load measurements. Finally we had experiences with coding and utilizing raspberry pi to communicate with the robot, ultimately gaining a full scope of the capabilities of the redesigned robot. Our redesign has thus proven very promising and our preliminary tests have been successful. We are excited to see where Tatum takes our project next! This summer has been an amazing experience. At tatum we gained a comprehensive understanding of the engineering process, from design intent to understanding the goal and the people we’re serving, educating every decision to be made throughout our project.

Shayna (rising senior at Thayer Academy)

During my two-week internship at AccuRounds, a manufacturing company, I had the opportunity to gain hands-on experience in programming a collaborative robot (cobot) and engaging in 3D modeling. This experience provided me with valuable insights into the integration of advanced technologies in modern manufacturing processes. I worked under Matt Pham and he was able to go into immense detail about any questions I had. I loved having him as a mentor and he taught me so much about the company.

Programming the cobot was one of the most exciting aspects of my internship. I was introduced to the basics of robotic programming and given the chance to work on a real-world project. The cobot was designed to assist in various tasks, such as assembly and quality control, which required precise programming to ensure accuracy and efficiency. Through this experience, I learned how to write and debug code, set up the robot’s work environment, and optimize its performance. This not only enhanced my technical skills but also gave me a deeper understanding of automation and its role in improving manufacturing productivity.

In addition to programming the cobot, I also worked on several 3D modeling projects. Using industry-standard software, I created detailed models of components and assemblies that were integral to the company’s manufacturing processes. This experience allowed me to apply my knowledge of engineering principles and improve my proficiency in 3D modeling. I learned how to create accurate and functional designs, which were then used to guide the manufacturing process. The ability to visualize and manipulate 3D models was crucial in identifying potential issues and making necessary adjustments before the actual production, thereby reducing errors and saving time.

Overall, my internship at the manufacturing company was an invaluable experience. Programming the cobot and working on 3D modeling projects significantly contributed to my understanding of advanced manufacturing technologies. These skills are not only relevant in today’s industry but are also essential for the future of manufacturing. The hands-on experience I gained has inspired me to maybe pursue a career in this field, with a focus on integrating technology to enhance manufacturing processes.

Bea (rising senior at Brookline High School)

This summer I had the opportunity to intern for Sea Machines Robotics, a company that focuses on creating navigation and autonomous control systems for commercial and recreational boats. Their technology enables boats and ships to operate without human intervention, improving maritime operations’ efficiency, safety, and reliability.

During my internship, I spent a considerable amount of time aboard The Maverick, one of their specialized workboats, under the guidance of Captain Kelsey Longhi. Most of our days were spent testing out their collaborative following, as we had just added the ability to change the mothership dynamically. This upgrade meant that Maverick could autonomously follow any designated ship, even if the leading vessel was changed, without any human interference. In case the vessel lost power, we made sure the return to flag commands worked properly. Those gave us the ability to set a “flag” on a desired waypoint that the vessel would navigate to in case of communication loss. Along with both of those, the feature that impressed me the most was obstacle avoidance. This gave Maverick the ability to tell the difference between static and moving obstacles, and in turn, change the course it took to avoid it and keep itself safe. We tested this from 25, 50, and 100m. One key tool that helped us with that was AI-ris which was an AI robot that was able to detect and categorize various types of obstacles such as different boats and buoys. AI-ris ingests 4K imagery with a single camera and uses embedded Sea Machines software to process it in real-time. I also spent some time with Daman Yang, one of the company’s engineers, as we constructed a brand new SM360 from start to finish, and fixed an AI-ris model that had failed due to creating smoke on one of the customer’s boats. Daman taught me things such as resistance and Ohm’s law, power distributions, and types of circuits. I also picked up on a lot of the hand tools commonly used. I spent a lot of time on confluence as Daman had written some documents he wanted me to look over. I also helped with the company’s connection to Rolls Royce! We worked on some of their computers before sending them back out.

5 weeks felt too short to be with such an amazing company, they made a lot of progress within a short period, and I feel incredibly thankful to have been a part of it. Moving forward, I’m interested in engineering but still want to keep connected to the ocean in some way.

Carlie (rising sophomore at Harvard University, from Jumpstart Cohort 3)

Carlie used her Engineering design process, CAD and networking skills she learned at Jumpstart during her summer internship at Shell TechWorks. Carlie writes:

Throughout my time at Shell Techworks I have seen how asking questions can guide a project and it helps to get a look at the bigger picture, which in turn allows me to progress within various projects. I have spent a lot of my time working with CAD and designing components for our direct air capture system. In addition to this, I have spent my time designing a cart for a purge extruder. With time, I have been able to strengthen my CAD skills, in solidworks. I was also introduced to FEA and have a general understanding about this process. I have also learned more about manufacturing processes and thus I am able to take this into account when working on designs. Lastly, there is a emphasis on safety at Shell TechWorks which has changed the way I conduct certain tasks either in the machine shop or in the office. Keeping safety in mind at all times creates a more safe work environment which I find very important and is something I admired about the culture at Shell Techworks. Overall, I had a great experience working at Shell Techworks and I have gained valuable knowledge and experience during my internship!

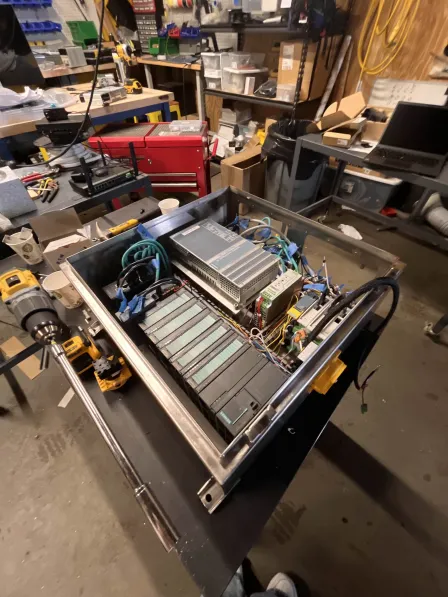

Ava Robotics brings a deep technical heritage, established at iRobot, to define and enable new opportunities for intelligent robots in the workplace. With this technology, our Ava Robot works to improve human productivity, safety, and quality of life for workers and customers of businesses across industries. Ava Robotics hosted 2 Jumpstart interns this summer. Here’s what they have to say:

“I have been lucky enough to have spent five weeks over the summer working for Ava Robotics. Ava is a telepresence robot used in commercial (most commonly factories) and medical settings. With Ava you can hold meetings and visit sites without the travel expenses. I was able to work on an array of tasks throughout my time at Ava Robotics. From changing out blown wires to assembling entire codec kits for a prototyping project. While the physical work is a great experience, I had some great mentors. Working with Nicholas, Greg, Marcio, and as well as Lucy, another Jumpstart fellow, everyday was a blessing. I gained a lot of perspective on what this industry really is and how much there is to learn outside of a textbook. I truly cannot thank Ava Robotics and Marcio and Youssef for this opportunity.” – Caitlin

“I spent my summer working as an intern at Ava Robotics. While there I work on many different projects, juggling different tasks. Some of them were constructing wire kits for the new robots they are getting ready to ship and running many tests for correct function. I learned many skills that I would have been able to learn without this hands-on experience like problem solving, professionalism, time management, and leadership. Not only that, I learned how an office runs and what it is like to work as an engineer.” – Lucy